Announcement

Collapse

No announcement yet.

EkI a good (friedrich orth) iron cross?

Collapse

X

-

Thanks again for the pics.

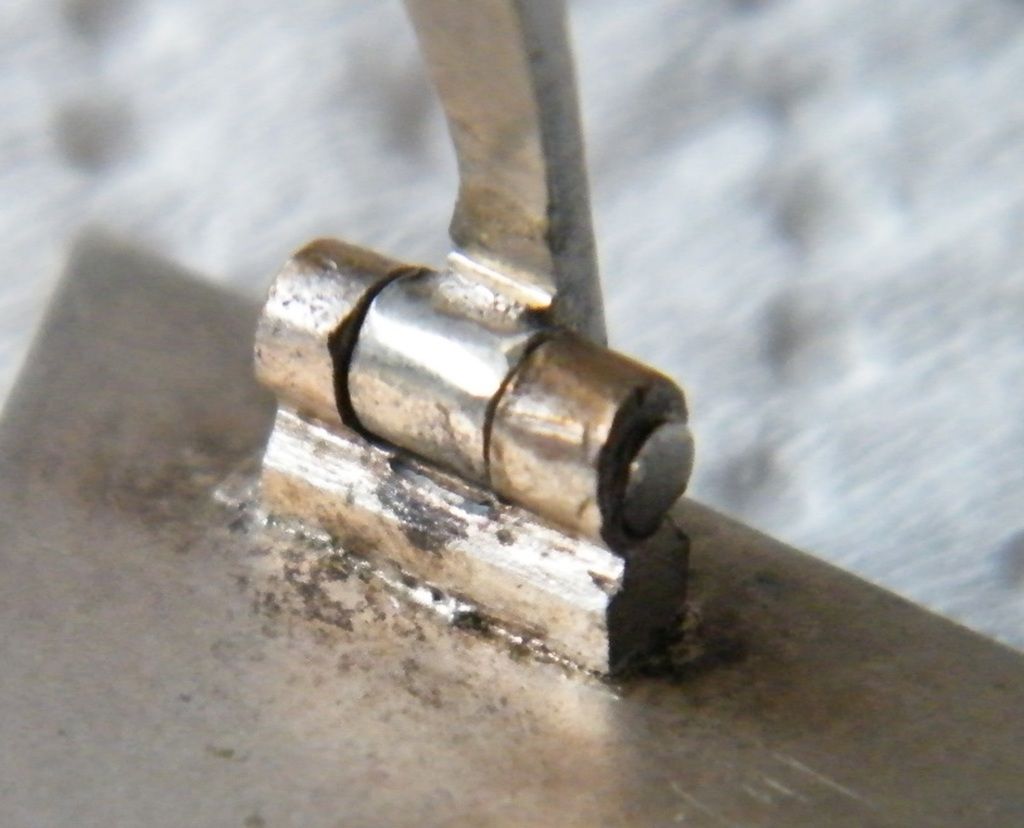

To me, looking at the wrong position, the wear of the hinge and the irregular solder view as a whole, I think the soldering in the hinge broke and then was resoldered in a wrong position; this is not an esay job without damaging the cross...it is only my opinion, of course.

On the other hand, it seems a rare Schenkl first class iron cross, somewhat polemic as this maker wasn't authorized to build first class iron crosses.

Comment

-

The most usual position of the hinge bar was flat (let's see Orth production).

Sometimes the hinge was vertical, and then a "stopping post" was needed. In most of the cases it was build as part of the pin's head (for example, you can see it as a small flap under the pin's head in the Walter & Henlein production from Gablonz, or in the Souval postwar iron crosses with the bended-and-soldered iron pin and later with S&L frame and the round wire one-piece bended pin), but in rare cases it was buid in the own hinge or soldered to it (this is the case of the "24" marked iron crosses from Arbeitsgemeinschaft de Hanauer Plakettenhersteller, if you check the pics in a database you'll see it clearly).

Many maker used both systems during their whole production.

I hope it helps you.

Originally posted by Blackopps View Post

Comment

-

During ww1 and interwars period there was a great experimentation in fixing devices for the badges, but during ww2 only some very early examples are different than the standard solution, a machined bar hinge that can be soldered in two positions:

Flat hinge: no "stopping post" needed, so the pin or needle construction is easier.

Vertical hinge: more surface for soldering and so more strong design, but more complicated pin construction.

Comment

Users Viewing this Thread

Collapse

There are currently 3 users online. 0 members and 3 guests.

Most users ever online was 10,032 at 08:13 PM on 09-28-2024.

Comment