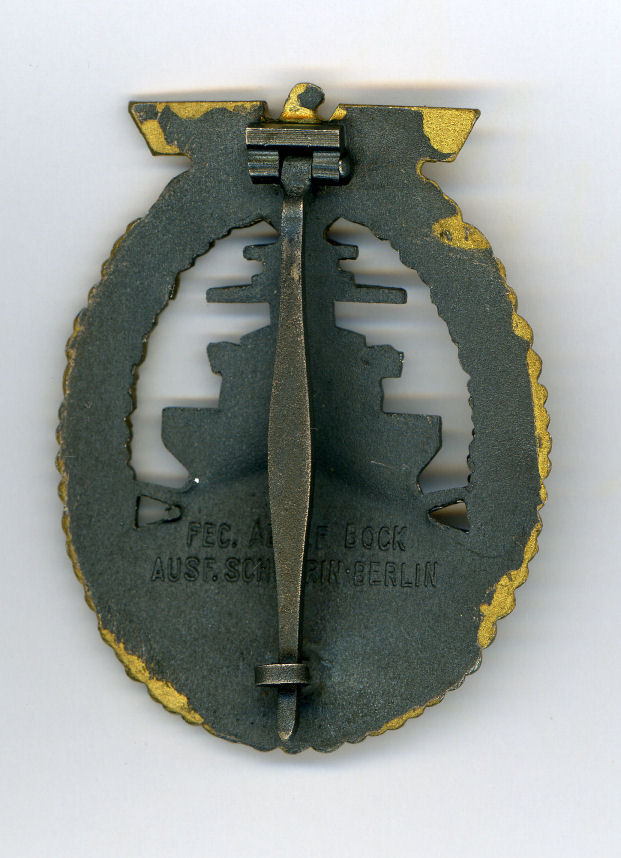

Reverse upper;

Announcement

Collapse

No announcement yet.

Mint HSF Badge

Collapse

X

-

Finish

Toby,

Please help me out here since I am not clear on a couple points. You said that there were two ways of gold plating a badge, then mentioned the pounce system. So three ways of plating a badge? Which is meant by you a s "fire gilt badges"? The normal way of applying the tombak finish, not gold plating?

In Robs description:

"The actual finish used varies depending on the individual award but they all generally comply with the following basic rules.

Tombak badges-- The finishes applied to these are extremely good and stand the test of time very well with any deterioration being caused by normal wear and tear / rubbing of the surface over the years. The order of the manufacturing process and application of finishes is believed to be as follows:

1. Production of the bare metal badge.

2. Hand finishing of small cutouts and edges, attachment of hinge, main pin and catch etc.

3. Application of a silver plate finish to areas where the “dark oxidised silver” is to be applied.

4. Application of dark “silver oxidised finish”.

5. Application of fire gilding direct to the obverse brass wreath. (It is common to see this finish spilling over onto the reverse side of the wreath also).

6. Burnishing of highlights on fire gilding e.g. swastikas, wreath highlights."

Then my question is, in a normal tombak badge, there is no gold, it is a combination of other metals but not gold. You are saying gold was or could have been used in some of the badges using the three systems you mentioned above but the Huss badge and your badge are not gold plated, but fire gilded. JohnLast edited by John R.; 05-26-2006, 09:26 AM.

Comment

-

Hsf

Hello,

The badge is beautiful but in my opinion it is fire-gilted. I have an identical example in my collection. The picture is not that great but it also has the same rich gold type of finish with polished highlights. I need to get a better picture of it.

It is still a top notch badge.

Regards,

Jody Attached FilesLast edited by Jody Beltram; 05-26-2006, 08:32 AM.

Attached FilesLast edited by Jody Beltram; 05-26-2006, 08:32 AM.

Comment

-

Schwerin AC badge

So we are saying no such thing as gold plated?

I am still at a loss to figure out my Schwerin AC badge lemon colored finish. No way in my opinion any amount of polishing did this. It did not go from the normal tombak colors to this lemon gold color by rubbing.

I am not sure what created the finish, but there is no overspill at all. A jeweler has looked at it, and is not sure, but thought it was gold plated. But a guess, and I sure do not know. He had a chemical process to find out, but no way I was going to scratch the badge.

The jeweler said it might be possible with a special gold brush like the one Toby described to the obverse to apply the gold plate.

JohnAttached FilesLast edited by John R.; 05-26-2006, 09:28 AM.

Comment

-

gold

This is what I would expect. The issue badges, especially the early ones, had fabulous finishes that were gold like in appearance, but not gold of course.

However, is there any evidence the men gold plated the badges on their own. I have not seen one, since I can't prove it one way or the other on my badge yet.

That means that the Huss badge is not gold plated, it is a perfect example of a mint fire-gilt tombak badge.

Comment

-

Hi John,

What I'm describing is the application of the gilt finish (the gold) to the body of the tombac badge. There is no gold in the body of the badge itself.

By plating I am referring to the electrolysis methods of applying a gold finish; fire gilding on the other hand, is a different method entirely and does not require electrolysis.

All this process requires is gold metal (fine gold) which is powdered to a fine dust. The gold dust is mixed with mercury to produce a paste. The purpose of the mercury is to act as a fixing agent since gold on its own will not adhere to the surface of the badge. The firing process causes the gold to fuse to the body of the badge (the mercury as mentioned before has burnt off).

Fire gilding as such is a centuries old method of affixing gold to a metal surface. The use of mercury didn't appear (in this country least) until the late eighteenth century. Prior to that honey was used as the fixing agent.

Re. Marc's post, if the process were merely the result of polishing, how do we explain the granular finish which is clearly visibile with a loupe and even from the photos posted here?

Toby.

Originally posted by trident3Tody,

Please help me out here since I am not clear on a couple points. You said that there were two ways of gold plating a badge, then mentioned the pounce system. So three ways of plating a badge? Which is meant by you a s "fire gilt badges"? The normal way of applying the tombak finish, not gold plating?

In Robs description:

"The actual finish used varies depending on the individual award but they all generally comply with the following basic rules.

Tombak badges-- The finishes applied to these are extremely good and stand the test of time very well with any deterioration being caused by normal wear and tear / rubbing of the surface over the years. The order of the manufacturing process and application of finishes is believed to be as follows:

1. Production of the bare metal badge.

2. Hand finishing of small cutouts and edges, attachment of hinge, main pin and catch etc.

3. Application of a silver plate finish to areas where the “dark oxidised silver” is to be applied.

4. Application of dark “silver oxidised finish”.

5. Application of fire gilding direct to the obverse brass wreath. (It is common to see this finish spilling over onto the reverse side of the wreath also).

6. Burnishing of highlights on fire gilding e.g. swastikas, wreath highlights."

Then my question is, in a normal tombak badge, there is no gold, it is a combination of other metals but not gold. You are saying gold was or could have been used in some of the badges using the three systems you mentioned above but the Huss badge and your badge are not gold plated, but fire gilded. John

Comment

-

Then you are saying that the tombak badges did have a small amount of gold applied with mercury on all tombak badges for their finish? Then Huss is correct in saying his badge is gold plated? But Marc has had it tested and found no gold on the tombak finish at all.Originally posted by TobyRHi John,

What I'm describing is the application of the gilt finish (the gold) to the body of the tombac badge. There is no gold in the body of the badge itself.

By plating I am referring to the electrolysis methods of applying a gold finish; fire gilding on the other hand, is a different method entirely and does not require electrolysis.

All this process requires is gold metal (fine gold) which is powdered to a fine dust. The gold dust is mixed with mercury to produce a paste. The purpose of the mercury is to act as a fixing agent since gold on its own will not adhere to the surface of the badge. The firing process causes the gold to fuse to the body of the badge (the mercury as mentioned before has burnt off).

Fire gilding as such is a centuries old method of affixing gold to a metal surface. The use of mercury didn't appear (in this country least) until the late eighteenth century. Prior to that honey was used as the fixing agent.

Re. Marc's post, if the process were merely the result of polishing, how do we explain the granular finish which is clearly visibile with a loupe and even from the photos posted here?

Toby.

Comment

Users Viewing this Thread

Collapse

There are currently 9 users online. 0 members and 9 guests.

Most users ever online was 10,032 at 08:13 PM on 09-28-2024.

Comment