by Sebastián J. Bianchi

Characteristics common to Iron Cross 2nd and 1st Class

The Iron Cross 1939 was similar in shape to its predecessors, that is a Maltese Cross (more accurately a Formee Cross), of course with the significant exception that the old crown, oak leaves and initials that were the heart of all previous Imperial Prussian Crosses were replaced by a new set of features centered around the Nazi Swastika.

This section describes the manufacturing process, which was virtually the same in the first two classes of the Iron Cross, and even the Knight's Cross. Additional details particular to each grade are reviewed in their respective sections.

Technical Information

The 1st and 2nd Class of the 1939 Iron Cross measured 44mm and were perfectly symmetrical, while the Knights Cross measured 48mm.

Although it was distributed in great numbers, the superior quality of the crosses manufactured remained consistent. World War II was the first mechanized war, and the technological advancements were carried over to the awards industry - where previous Iron Crosses had been manufactured largely by hand, the Iron Cross 1939 was mass produced.

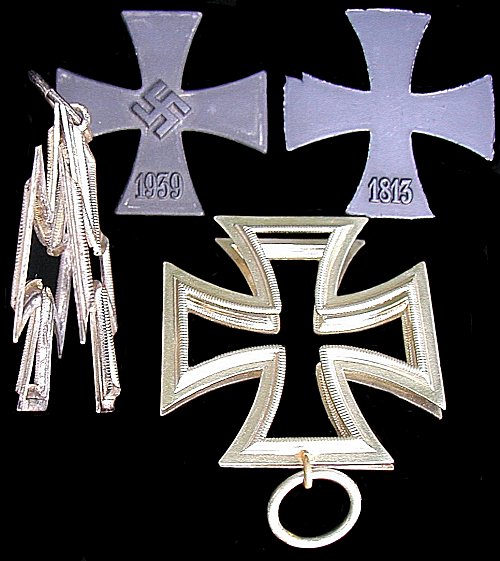

On the obverse, all grades featured a mobile swastika in the center, with the year 1939 on the bottom arm of the cross. The reverse in the 2nd class was devoid of detail except for its year of original institution, 1813, placed on the lower arm. The first class, being a breast badge, featured a plain silvered reverse with only the fastening mechanism (a pin or "screwback", discussed in the 1st Class section). As with most Iron Crosses the 1939 version was constructed of three pieces; the iron core, an obverse and a reverse silver frame.

The three sections of the Iron Cross can be seen in this picture

Sebastián Bianchi Collection

A period magazine article described the process as follows,

"The Knights Cross of the Iron Cross, similar to the Iron Cross I and Iron Cross II, is created as follows: The rim is made of massive silver, the black middle piece is made of iron. After both parts are combined, the rim gets bleached and the iron blackened. The carrying ring has been soldered on prior to this process. The outer rim of the silver casing gets polished, while the pearly ripped outer rim remains white.

All parts go through a final handling by the creator of the medals. Rings are hooked to the Knights Cross, the ribbons are pulled through it and the cross gets packaged in boxes and then they are delivered to the Presidential Chancellery of the Führer - the Medal Chancellery of the German Reich. For the Oak Leaves, the Oak Leaves with Swords as well as Oak Leaves with Swords and Diamonds there is always a distinguished different box available, made of black Spanish leather." (click here to read the entire article)

Frames

Most frames, or rims, were constructed of polished and lacquered “German silver”, an alloy of copper, zinc and nickel, although a few rare examples may be found made of non-plated zinc frames. As one would expect, these have a dull look to them. It has been speculated both that these zinc frames originated at the end of the war, and that they date to the very beginning of it prior to 1941, before the LdO started enforcing quality control. Which assertion (if either) is correct will probably never be proven.

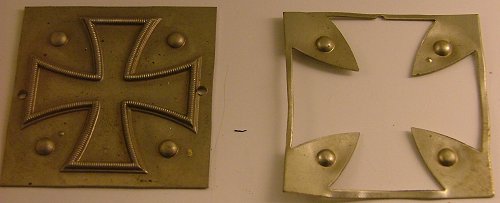

The opposite halves of the frame were struck separately with dies that yielded a smooth rim and crisp beading. Two methods were employed for manufacturing during the war,

1) "Blanking Die" Method; From the beginning of the war to 1942, the manufacturing process went as follows; The first operation, on a blanking die, stamped the shape of the frame into a thin sheet of silver. The center of the cross was not punched out and the area between each of the arms was likewise solid. This sheet metal was then placed on a finishing die, which cropped off all the excess around the shape of the rim.

Frame plate (before punch) and punched out waste

Frames after punching out

Series of manufacturing photos courtesy Sal Williams

2) "Gablonzer Press" Method; In late 1942 a similar but more efficient method, known as the "Gablonzer Press", was introduced. This construction technique, which resulted in considerable savings in material, dictated that a strand of wire 4.5 mm think be wrapped in an outline resembling that of the Iron Cross rim. This, instead of the entire sheet of metal, was then struck into the pattern of the frame, with a finishing die cropping off the excess material. Because there was not as much material to crop off the new method resulted in a 40% reduction of waste, although only a limited number of manufacturers switched to this method.

The final step of frame preparation involved the eyelet, which was soldered on by hand to temporarily hold the two halves together. The rim was now ready to accept the center core, and the rims were soldered together. Once soldered, a "Jeweler Stick" was used to run frosting on the flanges.

|

|

|

An Iron Cross separated from its core. Sebastián Bianchi collection |

Iron Core

The core of the award was normally solid iron, painted flat/semi-flat black and then baked to cure the enamel. The striking of the core was also a two part process - a first strike to form the shape, and the second strike to remove the rough edge left around it.

Photos courtesy Sal Williams

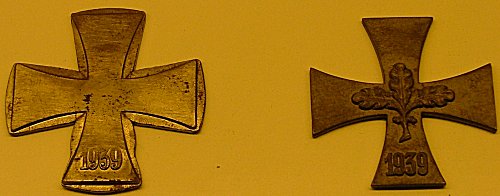

This central piece of the award usually possessed a high degree quality, for a military decoration produced in such quantities, with crisp details and sharp edges being the norm. Within these attributes, there is a spectrum of quality by manufacturer as some show more "blur" to the finish than others. Still, this "blur" is not to be confused with sloppy construction - it is simply a slightly rounder or softer look.

The actual details of the core, the Swastika and dates, also vary from maker to maker. Some Swastikas were high and were level with the rim, while others were slightly lower than the rim. Similarly no standard can be placed to the dates in the relation to the rim since these also range a few millimeters up or down, although they should never be touching the rim, and should without very few exceptions be parallel with the bottom arm.

|

|

|

|

Two examples of the Iron Cross. The one the the left, unmarked, has shaper details and is matt, while the one the the right (L/13) is semi-gloss and has a slight "blur" to the finish. Sebastián Bianchi collection |

|

The iron core was finished in a mat or semi-mat black and lacquered to protect from rust and wear. The system has generally stood the test of time, but is not uncommon to find Iron Crosses with partially rusted centers. There is also a rusting phenomenon that may be observed in some Iron Crosses called "veining", a series of raised canals which look like veins going across the award. These "veins" are caused by rust forming underneath the baked finished.

Non-Magnetic Cores

There are exceptions to the core being iron as some Iron Crosses have a non-magnetic brass center. It had been put forth for many years that these Crosses were used, or at least preferred, by Kriegsmarine personnel (a reasonable assumption, one can imagine iron would not last long exposed to the salty atmosphere of the high seas). This assumption, however, has not been documented and has actually fallen out of favor in the collector's world. More accurate seems the notion that non-magnetic Iron Crosses were issued prior to the LdO flexing its muscle, as in July 1942 a notice was published in the Uniformen Markt (industry trade magazine) reading as follows;

"Recently, three firms have used brass and tombak plated iron for the center of the Iron Cross First Class. I thereby advise all firms that the regulations issued the Präsidialkanzlei des Füheres must be strictly adhered to. In the case of the Iron Cross it is particularly important , on history and ethical grounds, that materials other than iron for the inserts must not be used. If these incidence reoccur, I will remove the offending firms from the list of authorized manufacturers." (1)

One can only assume that the firms that were out of regulation fell in line and resumed the exclusive use of iron for all Iron Cross centers.

Assembly

When the two halves were soldered the finished product was exceptionally neat, with only the slimmest of lines present. Most crosses will show evidence of filing all around the edges, although in some cases magnification may be needed to see it. The end points of the cross were hand filed to be slightly curved and this fact, combined with the natural erosion time takes from edges, means that the points of original Iron Crosses today should never feel sharp to the touch.

|

Click on images to enlarge |

|

|

Soldering line and file marks of an Iron Cross |

The roundness of the corners can be appreciated in this picture. |

Once the center was applied it was usually held securely in place by the construction, although in some early Iron Crosses it is possible to rattle the iron inside of the frame. While it is indisputably a rare find, an Iron Cross that has maintained its gleaming silver finish through the years is indeed a site to behold. More often than not surviving crosses have developed an aged look - the collectors' patina. The rim of these crosses have a look that ranges from beige to almost brownish. Although these are not as immediately striking they are non-the-less visually powerful; the patina gives away that the cross has seen the passing of the years, it gives it that antique feel. Which "look" is preferred is only a matter of personal taste - the cross as it would have been received by a soldier, or one that was perhaps received, worn, and shows its age.

|

|

|

Two extremes - an Iron Cross which has developed quite a bit of patina, and one that has preserved its mint frost finish. Sebastián Bianchi collection |

![]()

© Copyright Wehrmacht-Awards.com LLC |